surface vision

For Your Development Safety

OUr Best Service

Your Ultimate Solution

Choose Your Plan

Product

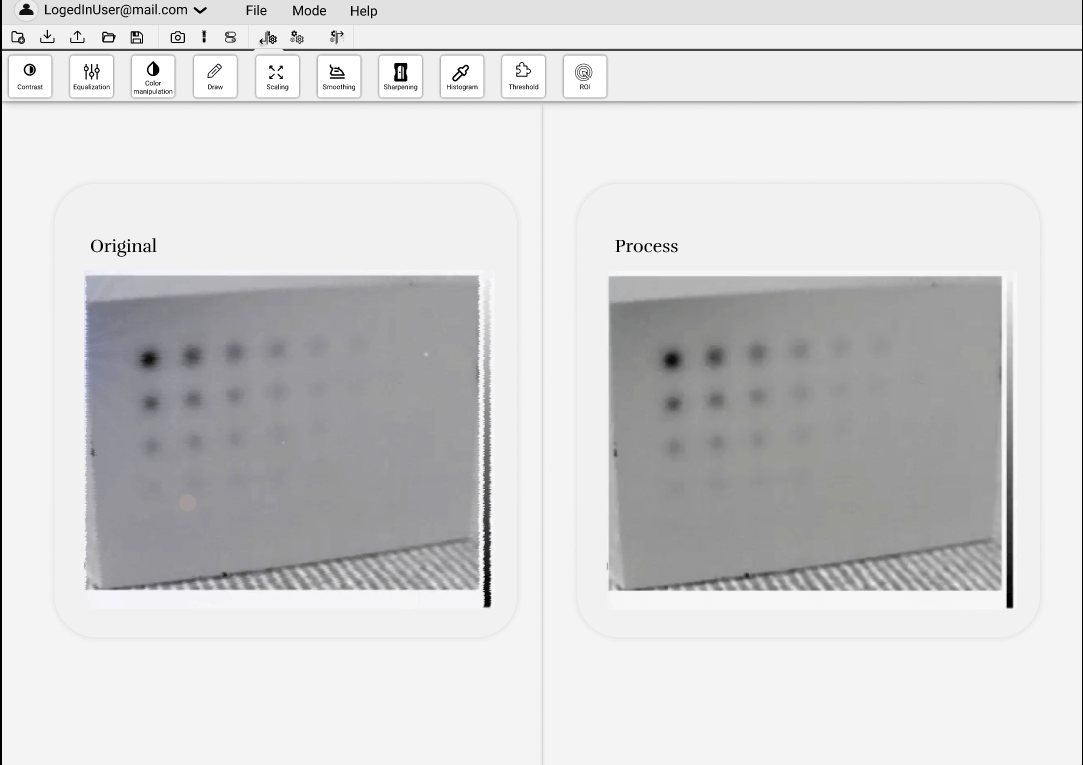

AI based image processing solution will be performed to find the defect defects on the target

we offer a noncontact and noninvasive defect detection based on IR thermography

To enhance the detection speed and image contrast we will utilize the active IRT approach by a continuous laser source with appropriate wavelength

Scanning Laser Spot approach would be employed to check the whole region of interest (ROI)

surfvision

InfraRed Imaging Defect Detection

Specifications:

- Profile Scanner

- Graph

- Thermal Mapper

Profile Scanner:

- Visible: defects are detected in visible channel by RGB camera

- Infrared: Conduction/resistance ability over the surface or near the surface in active mode, as well as thermal distribution over the sample in active/passive mode is provided

Graph:

- Visible: provide a single/big and high resolution visible image from the sample. Post processing algorithms produce results in graphs and shapes. The image may be in 3D or 2D visual state

- Thermal: like visible 3D/2D images, thermal image may be produced in visually sensible state. Here the thermal image shots may be recorded continuously and the results may be graphed in 3D/2D drawings

Mapper:

mostly there is not a vivid effect over sample relating to the defect. Even post processing data may be not visual information. Mapping is a proper way to make the results sensible

our services

Software

Software properties:

Processing video/image mode

Color graph

3D/2D graph

Extracting results

Individual Profile up to 10 profiles

Preprocessing

Post-processing

Frame base graphing

Scaling tools

About Us

Your Ultimate Solution

Fidelity in manufacturing and production needs professionality in Quality Control (QC). Defects are inevitable in producing but they are controllable and reducible. Also it is important to find the procedures and actions burning and causing defects. The defects may be created in structures too. Therefore quality and health monitorings are fatal for parts and structures. They realize that a proactive approach to monitoring will be cost-effective. Technology advancements related to safety in the inspection made it possible to monitor defects. Varieties of advanced methods have been used to detect defects of infrastructure, such as VT, MT, UT, ET, and image processing with AI. These tests are mostly offline, costly and time consuming. It will be most effective and cost-effective to use inline, online and local apparatus.

SurfVision Industrial NDT Company will leverage its competitive edge in providing an affordable, accurate, and inline/offline device to automate QC of product and to quantify the qualitative monitorings. This apparatus is a hardware with software included for presence of crack, erosion and welded joint composite defects as well as health monitoring review. The product is an active laser-included thermography camera accompanied by visible photography and complementary apparatuses as well. SurfVision system is used by QC-engineers and detectives. SurfVision system integrates nondestructive and noncontact detections and measurement, performs data processing to provide relevant reports and dashboards for managing project.

Contact us

Get in Touch

Powered by Surface Vision © 2021 | All Rights Reserved.